TRIVETTE HISTORICAL PICTURES - 1 OF 3

-- 1974 --

It was February 20th, 1974, when the first article appeared in the Ventura Star-Free Press showing the scale model of the vehicle. On

March 11th, 1974, Transportation Concepts Company (a limited partnership) was formed, with 10 investors at $1,000 each.

It was February 20th, 1974, when the first article appeared in the Ventura Star-Free Press showing the scale model of the vehicle. On

March 11th, 1974, Transportation Concepts Company (a limited partnership) was formed, with 10 investors at $1,000 each.

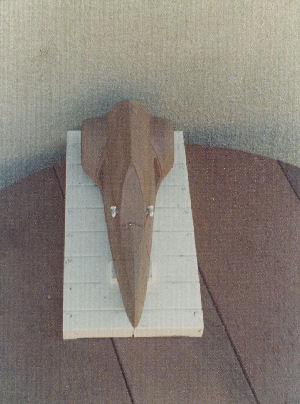

This is a picture of the scale model. The rear view mirrors are from a plastic kit of another car.

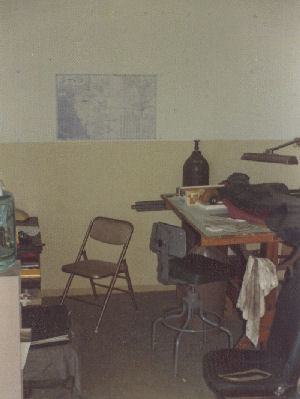

This is the shop on 1330 Callens Road where the work of designing and building the prototype began. This shows a picture of Bob's

drafting table and desk. If you look closely you can see the scale model of the car. This is the drafting table that all of Bob's

vehicles were designed on and he continued to design on for the rest of his life.

This is the shop on 1330 Callens Road where the work of designing and building the prototype began. This shows a picture of Bob's

drafting table and desk. If you look closely you can see the scale model of the car. This is the drafting table that all of Bob's

vehicles were designed on and he continued to design on for the rest of his life.

One of the work tables used in the shop. This picture was taken around June of 1974.

One of the work tables used in the shop. This picture was taken around June of 1974.

Another picture of the shop complete with "Welder Boy" as Bob was known then. You can see some of the TriVette parts, tires, etc.,

lying around.

Another picture of the shop complete with "Welder Boy" as Bob was known then. You can see some of the TriVette parts, tires, etc.,

lying around.

Welder Boy welding the frame of the prototype using a MIG welder. He still has and uses that welder. The frame here is upside down

and you can tell it's the prototype because it's the only one that square tubing was used on. All of the production cars used

round tubing.

Welder Boy welding the frame of the prototype using a MIG welder. He still has and uses that welder. The frame here is upside down

and you can tell it's the prototype because it's the only one that square tubing was used on. All of the production cars used

round tubing.

This is the full size plywood form before it was sent to the "foaming" shop.

This is the full size plywood form before it was sent to the "foaming" shop.

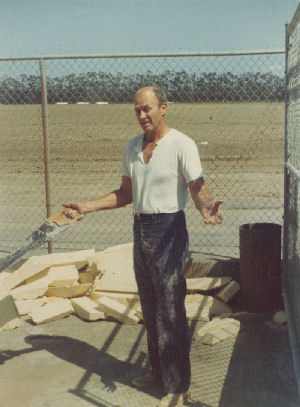

The wood form was taken to a place in Oxnard California to be foamed, where they made large planters for malls and such. The foam was

actually used on the outside of the planters, etc. for shipping protection. The plywood mockup was then sprayed by them and it's shown

here at the shops side yard. Behind this is the motorhome chassis that Bob was working on for American Motors.

The wood form was taken to a place in Oxnard California to be foamed, where they made large planters for malls and such. The foam was

actually used on the outside of the planters, etc. for shipping protection. The plywood mockup was then sprayed by them and it's shown

here at the shops side yard. Behind this is the motorhome chassis that Bob was working on for American Motors.

One of the partners, Dick Downey, helping cut off surplus foam using 2 adjacent plywood stations to guide the handsaw. This created

a segmented surface. Drywall compound was then used to smooth this surface.

One of the partners, Dick Downey, helping cut off surplus foam using 2 adjacent plywood stations to guide the handsaw. This created

a segmented surface. Drywall compound was then used to smooth this surface.

The unit was taken to the Ventura Marina where they applied fiberglass to the outside of the "plug".

The unit was taken to the Ventura Marina where they applied fiberglass to the outside of the "plug".

The plug was brought back to the shop and here they are "finishing" smoothing the surface of the fiberglass.

The plug was brought back to the shop and here they are "finishing" smoothing the surface of the fiberglass.

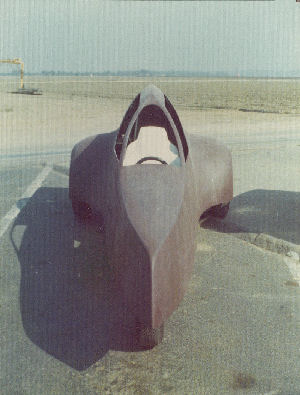

This shows the first fiberglass body for the prototype. At this point it has no headlights, taillights, doors, or returns around

the windows or the windshield. It is just the empty body form. To test the body design Bob and his son sat this body on top of the

chassis and Bob drove the car with one hand and his other hand held up the body. His son held the body up from the rear seat using

both hands. They then drove down the Freeway to ensure it was generating downforce!!!! At 55 MPH it generated so much downforce

that Bob couldn't hold it up anymore. It was then decided that that was sufficient downforce.

This shows the first fiberglass body for the prototype. At this point it has no headlights, taillights, doors, or returns around

the windows or the windshield. It is just the empty body form. To test the body design Bob and his son sat this body on top of the

chassis and Bob drove the car with one hand and his other hand held up the body. His son held the body up from the rear seat using

both hands. They then drove down the Freeway to ensure it was generating downforce!!!! At 55 MPH it generated so much downforce

that Bob couldn't hold it up anymore. It was then decided that that was sufficient downforce.

The original prototype chassis (without the body). You can see airshocks were used. This was because they didn't have the proper

coil over shocks at this point. This is still the shop at Callens Road. You can see a farm field here looking east from the shop.

This is the parking lot where the driving tests were done for the original prototype chassis. Bob had his kids sitting on his lap

steering it while he controlled the throttle. They were "screaming" around the lot doing brodies. The steering worked great from

day one - no changes were ever made to it!

The original prototype chassis (without the body). You can see airshocks were used. This was because they didn't have the proper

coil over shocks at this point. This is still the shop at Callens Road. You can see a farm field here looking east from the shop.

This is the parking lot where the driving tests were done for the original prototype chassis. Bob had his kids sitting on his lap

steering it while he controlled the throttle. They were "screaming" around the lot doing brodies. The steering worked great from

day one - no changes were ever made to it!

In the white shirt is Maurice Boucher, one of the original investors. Bob is in the maroon shirt.

In the white shirt is Maurice Boucher, one of the original investors. Bob is in the maroon shirt.

These two people were working on the master for the main body section. The work was done at Fibron at Compton.

These two people were working on the master for the main body section. The work was done at Fibron at Compton.

Working on the finished plug for the main body section. You can see the wooden bracing inside so that it holds its proper form.

Working on the finished plug for the main body section. You can see the wooden bracing inside so that it holds its proper form.

The final plug for the nose section and the engine cover. These are called the "master" and are the pieces that the actual molds

are taken from.

The final plug for the nose section and the engine cover. These are called the "master" and are the pieces that the actual molds

are taken from.

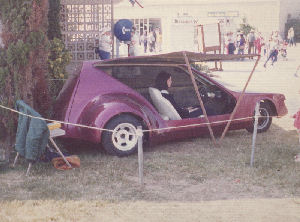

The Ventura County Fair in October 1974. This is the prototype vehicle, complete with white shocks and broomhandles holding up

the door!! The strut was installed later. It also still lacked headlights, mirrors, etc.

The Ventura County Fair in October 1974. This is the prototype vehicle, complete with white shocks and broomhandles holding up

the door!! The strut was installed later. It also still lacked headlights, mirrors, etc.

Around this time Bob took his car to a car show. He won an outstanding design award trophy for the TriVette that was presented

to him by the world famous automotive designer Alex Tremulus!! He was Henry Ford's chief designer for decades. He also designed the

Tucker Automobile.

The model inside the car is Bob's wife, Diana. This was the first public showing of the TriVette.

The model inside the car is Bob's wife, Diana. This was the first public showing of the TriVette.

The prototype in front of 2113 C shop on Palma Drive where the company had moved to. They were running out of room at the old

location and needed to expand. This prototype vehicle, before headlights, mirrors, window vents were installed, is now owned by

Bob's brother in Portland, OR.

The prototype in front of 2113 C shop on Palma Drive where the company had moved to. They were running out of room at the old

location and needed to expand. This prototype vehicle, before headlights, mirrors, window vents were installed, is now owned by

Bob's brother in Portland, OR.

Front 3/4 view of the round tube production frame. The prototype used a square frame and the production vehicles all used round

tubing. This was taken at 1499 Palma Drive, the company needed to move once again to a larger facility to accommodate the larger

production.

Front 3/4 view of the round tube production frame. The prototype used a square frame and the production vehicles all used round

tubing. This was taken at 1499 Palma Drive, the company needed to move once again to a larger facility to accommodate the larger

production.